Zipper for Packaging Bags

-

Payment

L/C(sight) , T/T

-

MOQ

5,000 meter (m)

-

Supply Ability

4,200,000 meter (m) per Month

-

Supply Details

Customization Sample Order

(MOQ) / 5000M

-

Country of sale

World Wide, Americas, Asia, Europe, Middle East

-

PRICE

-

FOB

USD 0.02 ~ 0.10

(1 meter (m))

-

ITEM SPECIFICS

-

Brand

Model PE-ZT13-C/EVA-DZ12-W/PP-ST10-BK etcPOLYKO

-

origin

Republic of Korea

-

Size(Capacity)

Customizable (width and length)

-

Function

For packaging and sealing

-

Material

PE (Polyethylene), PP (Polypropylene), EVA

-

Color

Transparent, Colored options available

-

Weight

Depends on size and type

-

Style

Press-to-close zipper, Slider zipper, etc

-

Condition

New product

-

Features

Strong sealing, reusable, customizable size and color

PRODUCT DESCRIPTION

Zipper for Packaging Bags

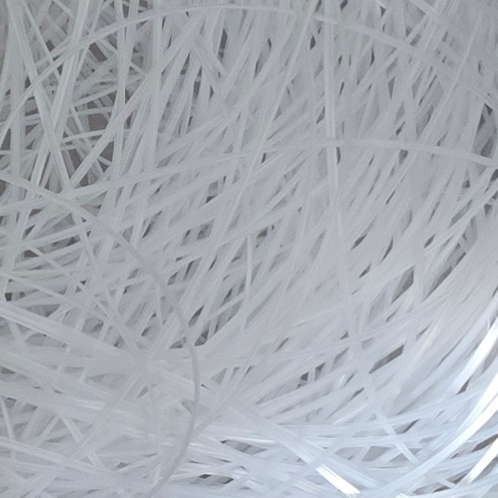

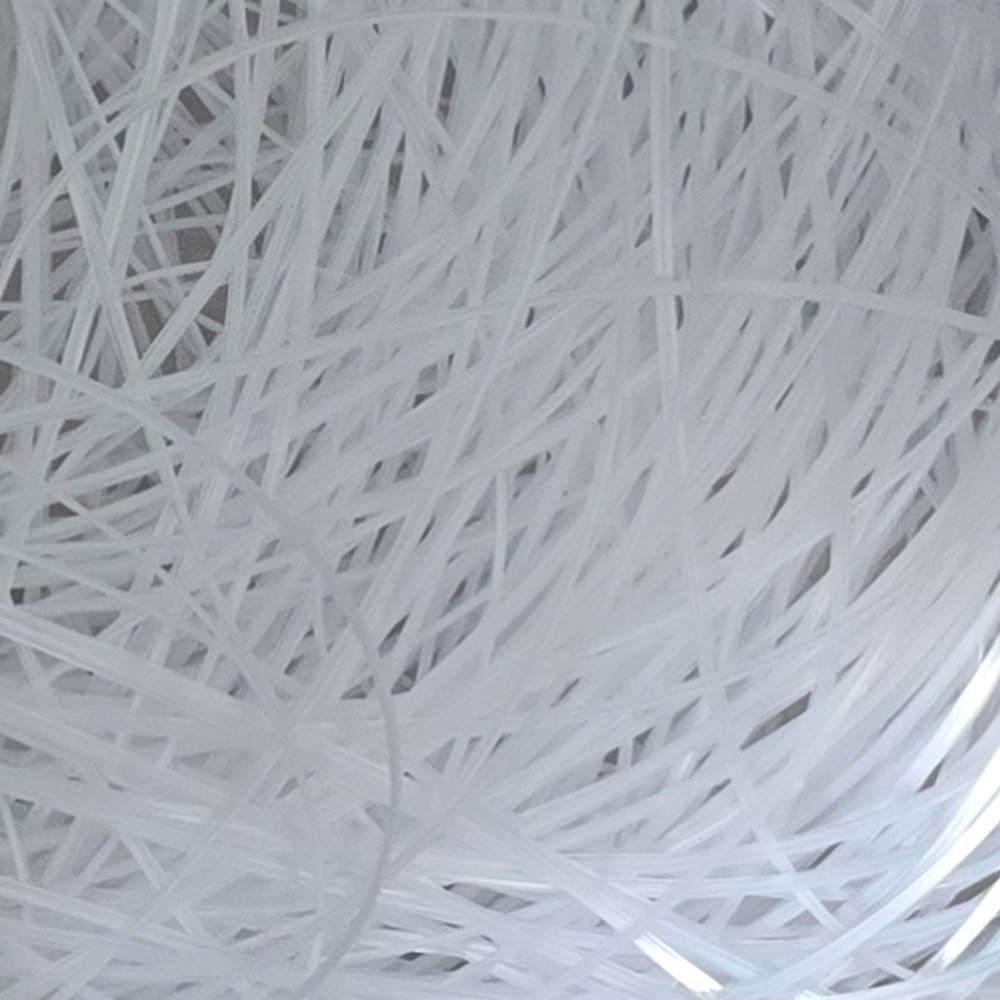

Our zipper product line is manufactured using PE (Polyethylene), PP (Polypropylene), and EVA (Ethylene-Vinyl Acetate), serving a wide range of industries including food, apparel, pharmaceuticals, and industrial components.

Each material offers unique benefits — PE is soft and flexible with reliable performance in low temperatures, PP has high rigidity and heat resistance suitable for microwave defrosting and high-temperature sterilization, and EVA provides excellent elasticity, sealing performance, and premium transparency.

Each material offers unique benefits — PE is soft and flexible with reliable performance in low temperatures, PP has high rigidity and heat resistance suitable for microwave defrosting and high-temperature sterilization, and EVA provides excellent elasticity, sealing performance, and premium transparency.

Produced through a precision extrusion process, our zippers are available in various structures and functionalities.

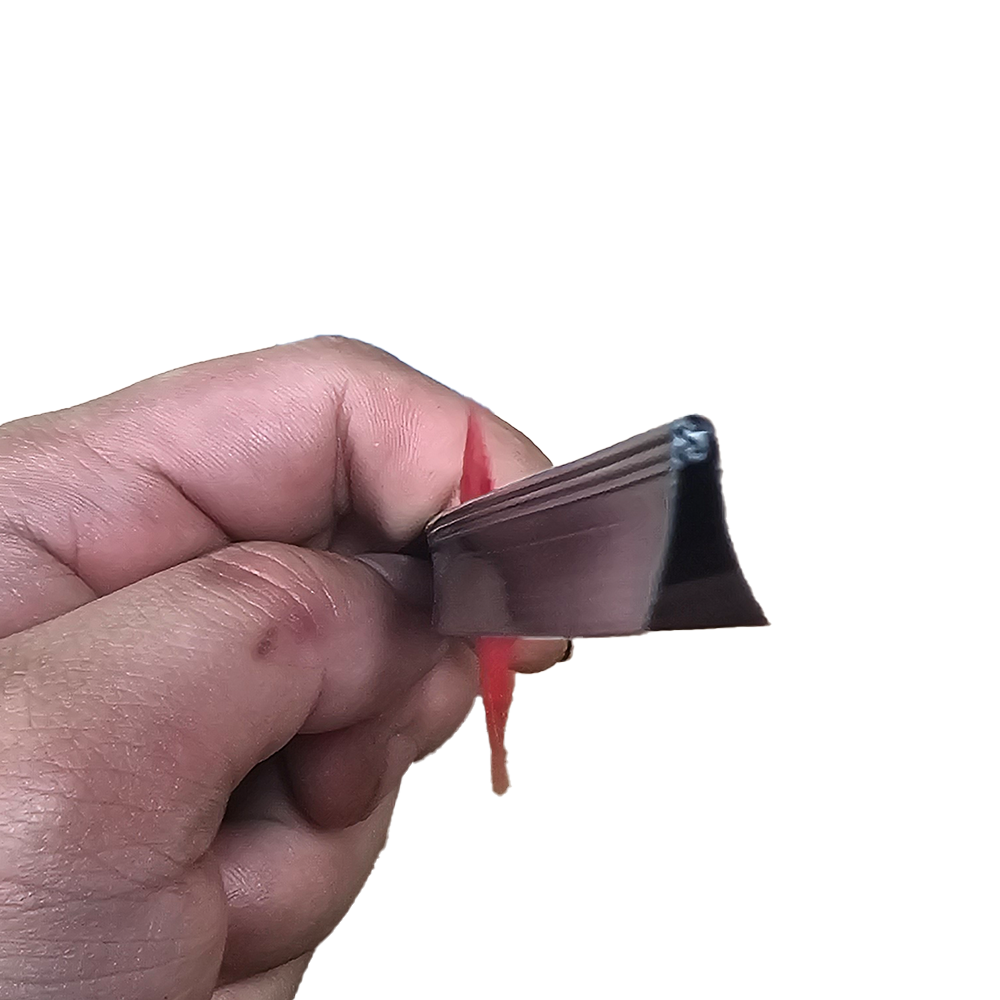

The single-track zipper offers smooth operation and quick packaging with a one-track closure, while the double-track zipper delivers enhanced sealing for long-term storage, liquids, powders, and frozen products.

The slider type zipper features an attached handle for easy operation, ideal for large-volume or frequently accessed packaging. The waterproof slider zipper incorporates a sealing design that prevents liquid or moisture ingress, making it perfect for liquid products or moisture-sensitive goods.

The wing zipper includes side extensions for compatibility with automated packaging machinery, boosting efficiency in high-volume production.

Additional functional options include anti-fog performance to prevent condensation in refrigerated or frozen storage, and freshness-preserving mineral additives to maintain the taste and aroma of packaged foods.

Our zippers can also be combined with high-barrier films for improved preservation and visual appeal.

Designed with eco-friendly single-material structures, our zippers are fully recyclable and can be customized in various specifications, colors, thicknesses, and widths.

This enables us to deliver high-quality, functional, and sustainable packaging solutions trusted by industries worldwide.

Company Overview

POLYKO Inc. is a leading Korean manufacturer of plastic packaging materials, specializing in PE, PP, and EVA film extrusion, zipper production, and zipper bag converting. With over 20 years of experience, we offer one-stop packaging solutions for apparel, food, baby products, and industrial use. Our factory is equipped with advanced extrusion and converting lines, ensuring stable quality and fast delivery. We support OEM/ODM orders, small MOQs, and eco-friendly materials. POLYKO is committed to quality, flexibility, and long-term partnerships with global clients.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Telegraphic Transfer : T/T

- Name : Yang Ki Jin

SHIPPING

Shipping from :

Republic of Korea

- 16 Gahyeon-ro Tongjin-eup, Gimpo-si, Gyeonggi-do (10038)

Polyko Inc.

The person in charge

Tae yong YangAddress

16 Gahyeon-ro Tongjin-eup, Gimpo-si, Gyeonggi-do (10038)

큐알

Polyko Inc.

Introduction

POLYKO Inc. is a leading Korean manufacturer of plastic packaging materials, specializing in PE, PP, and EVA film extrusion, zipper production, and zipper bag converting. With over 20 years of experience, we offer one-stop packaging solutions for apparel, food, baby products, and industrial use. Our factory is equipped with advanced extrusion and converting lines, ensuring stable quality and fast delivery. We support OEM/ODM orders, small MOQs, and eco-friendly materials. POLYKO is committed to quality, flexibility, and long-term partnerships with global clients.

-

- Business Type :

- Manufacturer

-

- Main Product :

- PE,PP,EVA Film(transparent,Matt,etc), Slide Zipper, Single line Zipper, Slide Zipper Bag, etc

-

- Established :

- 2000-03-01

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- Less than 5

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- Polyko Inc. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★