Tire Mold Patterning Rubber

-

Payment

T/T

-

MOQ

600 Kilogram (kg)

-

Supply Ability

9,999,999 Kilogram (kg) per One-Time

-

Supply Details

Customization

Part A 600kg, Part B 80kg

-

Country of sale

Asia, Americas, Europe, World Wide, Middle East

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model HKRUB300, HKRUB400HKRUB SERIES

-

origin

Republic of Korea

-

Size(Capacity)

Part A (200kg), Part B (20kg)

-

Function

A two-component liquid rubber that is used by mixing Part A and Part B in an appropriate ratio as a

-

Material

Polysulfide Rubber

-

Color

Black

-

Expiry Date

1years

-

Condition

liquid

-

Features

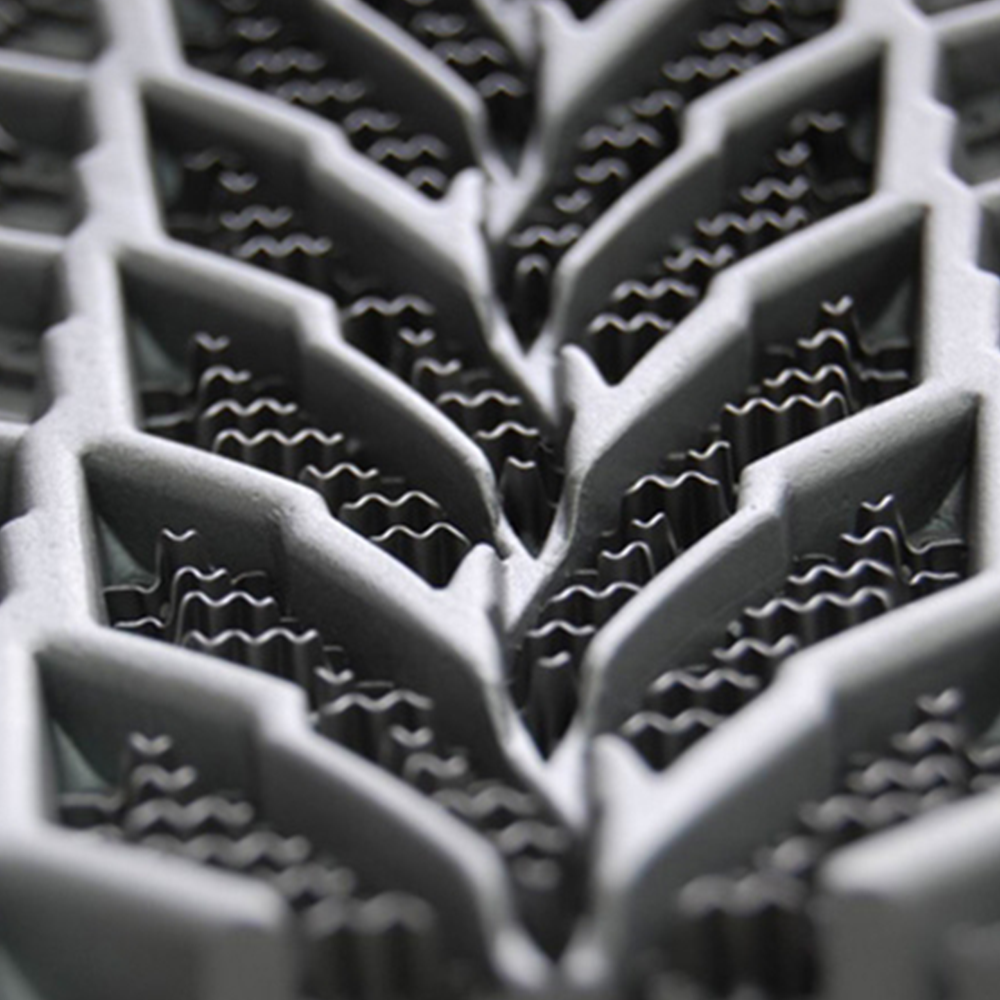

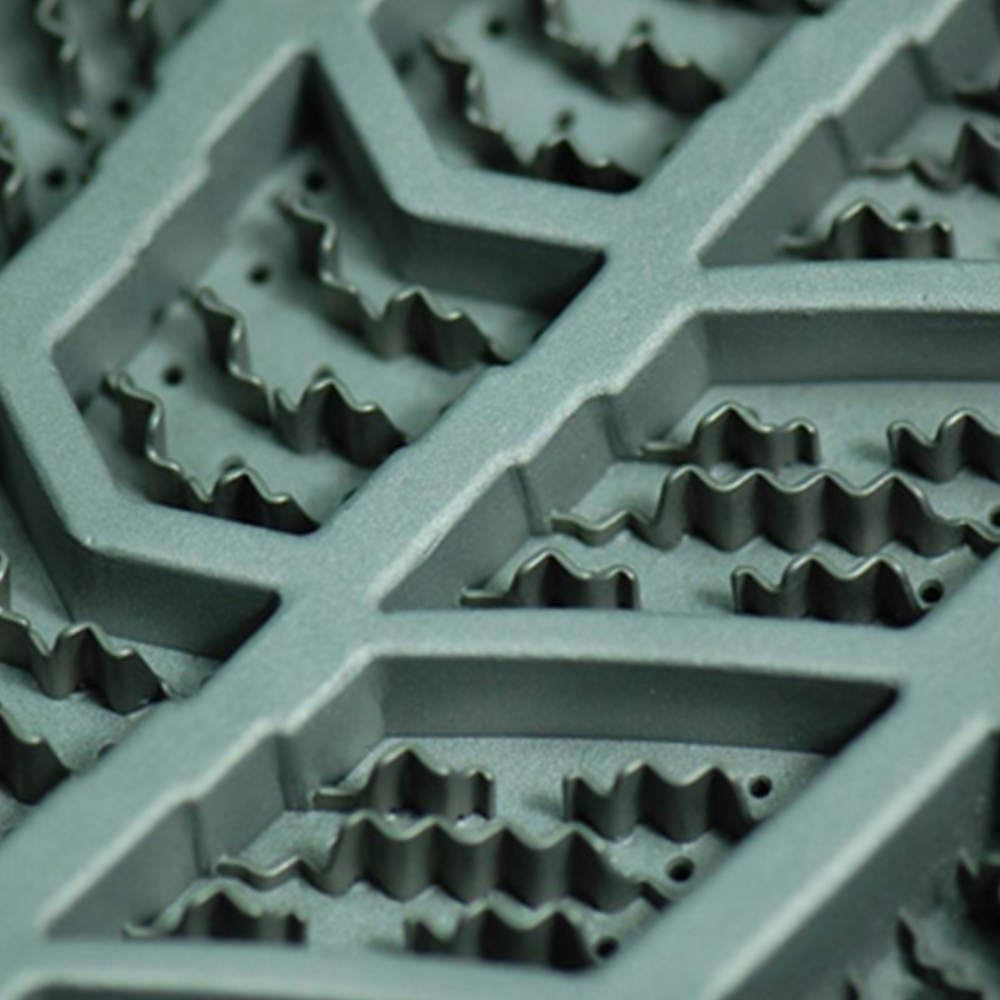

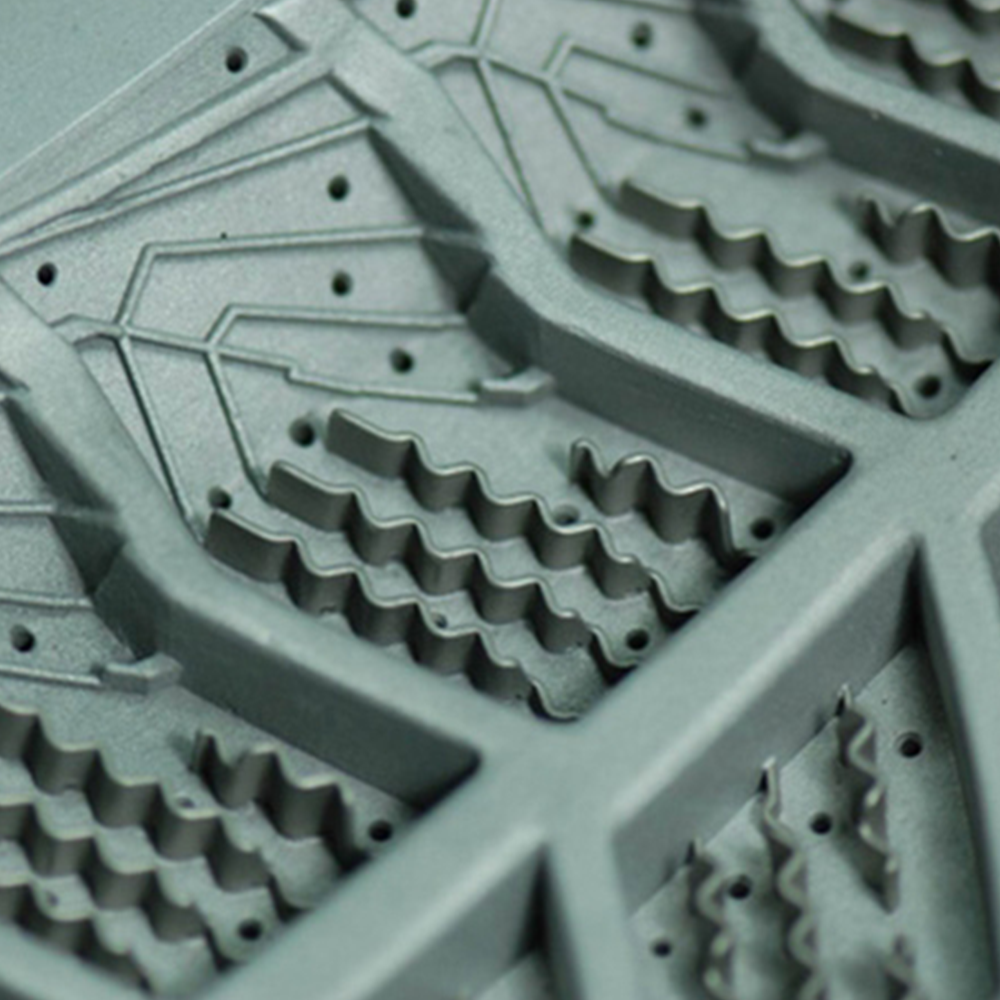

By optimizing the viscosity, it is possible to perfectly make a tire mold with a fine

PRODUCT DESCRIPTION

Tire Mold Patterning Rubber

Technical Parameters

· Excellent replication accuracy with a margin of error within 0.01%, ideal for mold-making rubber.

· Capable of replicating fine and complex patterns such as tire treads and metal molds with thickness as small as 0.2mm.

· Exclusive domestic proprietary technology.

· World’s first and only eco-friendly curing agent developed (as of now, globally unique).

· Applicable for casting tire mold production.

· Capable of replicating fine and complex patterns such as tire treads and metal molds with thickness as small as 0.2mm.

· Exclusive domestic proprietary technology.

· World’s first and only eco-friendly curing agent developed (as of now, globally unique).

· Applicable for casting tire mold production.

Key Features

Purpose

Two-component liquid rubber designed for replicating master models used in the manufacturing process of tire molds or similar metal mold products.

Effects / Benefits

By mixing the base material (Part A) with the curing agent (Part B) at the proper ratio, this product allows adjustment of viscosity and hardness to suit diverse user needs.

Main Functions

Provides excellent replication accuracy (within 0.01% deviation) and is capable of perfectly duplicating micro and intricate patterns such as 0.2mm fine tire treads or metal mold designs.

Advantages

Primary Advantages

Outstanding molding accuracy within 0.01% margin of error, allowing for precise replication of detailed patterns such as tire treads and metal molds.

Competitiveness

· Exclusive technology in Korea

· World's first eco-friendly curing agent

· Applied in actual tire mold casting

· World's first eco-friendly curing agent

· Applied in actual tire mold casting

How to Use

· For stable curing and performance, stir Part A and Part B separately for about 3 minutes before use.

· Mix Part A and Part B at a ratio of 100:14 in a clean container using a mixer for at least 2 minutes, ensuring thorough mixing along the container's sides and bottom.

· Use only the amount that can be poured within 20 minutes of mixing.

· The curing agent (Part B) can be used within a 13–16% range relative to Part A.

· Mix Part A and Part B at a ratio of 100:14 in a clean container using a mixer for at least 2 minutes, ensuring thorough mixing along the container's sides and bottom.

· Use only the amount that can be poured within 20 minutes of mixing.

· The curing agent (Part B) can be used within a 13–16% range relative to Part A.

Cautions

· Storage Temperature: 25–30℃

· Optimal Use Temperature: 23–25℃

· Safety Equipment Required: Safety shoes, protective goggles, rubber gloves, and mask

· Ensure proper ventilation during mixing

· Use as soon as possible after mixing

· Optimal Use Temperature: 23–25℃

· Safety Equipment Required: Safety shoes, protective goggles, rubber gloves, and mask

· Ensure proper ventilation during mixing

· Use as soon as possible after mixing

Certifications

ISO9001, ISO14001

Specifications

| Product Name | HKRUB Series |

| Model/Series No. | HKRUB300, HKRUB400 |

| Brand Name | HKRUB |

| Weight | Part A – 200kg / Part B – 20kg |

| Height | Part A – 90cm, Part B – 40cm |

| Width | Part A – 60cm, Part B – 30cm |

| Color | Black |

| Material | Polysulfide |

| Origin | Republic of Korea |

Company Overview

HANKOOK CHEMICAL & SYSTEM Co., Ltd. is a specialized materials and components company with a 45-year history, dedicated to the production of eco-friendly fine chemical products. Starting with the development of tire release agents and specialty paints used in automobile tire manufacturing, the company has focused on producing tire mold patterning rubber based on polysulfide polymer, which is essential in the production of tire molds.

In addition, aiming to introduce a new paradigm in the architectural interior and exterior materials market, Korea C&S has leveraged its accumulated expertise in synthetic rubber manufacturing to become the first in Korea to develop rubber molds for design concrete, enabling the production of aesthetically appealing design concrete panels.

For over 20 years, the company has also been supplying water treatment chemicals, and based on its know-how in equipment development and supply, it produces industrial cleaning agents and detailing chemical products for comprehensive automotive care.

In addition, aiming to introduce a new paradigm in the architectural interior and exterior materials market, Korea C&S has leveraged its accumulated expertise in synthetic rubber manufacturing to become the first in Korea to develop rubber molds for design concrete, enabling the production of aesthetically appealing design concrete panels.

For over 20 years, the company has also been supplying water treatment chemicals, and based on its know-how in equipment development and supply, it produces industrial cleaning agents and detailing chemical products for comprehensive automotive care.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : NA YONG BEOM

SHIPPING

Shipping from :

Republic of Korea

- 10 Cheomdanyeonsin-ro 29beon-gil, Buk-gu, Gwangju (61089)

Hankook Chemical & System Co., Ltd.

The person in charge

YONG BEOM NAAddress

10 Cheomdanyeonsin-ro 29beon-gil, Buk-gu, Gwangju (61089)

Introduction

HANKOOK CHEMICAL & SYSTEM Co., Ltd. is a specialized materials and components company with a 45-year history, dedicated to the production of eco-friendly fine chemical products. Starting with the development of tire release agents and specialty paints used in automobile tire manufacturing, the company has focused on producing tire mold patterning rubber based on polysulfide polymer, which is essential in the production of tire molds.

In addition, aiming to introduce a new paradigm in the architectural interior and exterior materials market, Korea C&S has leveraged its accumulated expertise in synthetic rubber manufacturing to become the first in Korea to develop rubber molds for design concrete, enabling the production of aesthetically appealing design concrete panels.

For over 20 years, the company has also been supplying water treatment chemicals, and based on its know-how in equipment development and supply, it produces industrial cleaning agents and detailing chemical products for comprehensive automotive care.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Tire mold patterning Rubber

-

- Established :

- 1978-10-10

-

- Total Annual Revenue :

- 2~3 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 2~3 billion (KRW)

-

- Total export revenue (previous year in USD)

- 122,897

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- Hankook Chemical & System Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

![[ZOMBIE] PLASTIC & LEATHER COAT](/image/goodsImage.do?goods_no=GS2021112310063&image_se_code=MAIN_THUMB174)

![[ZOMBIE] TIRE & TRIM COAT](/image/goodsImage.do?goods_no=GS2021112310060&image_se_code=MAIN_THUMB174)