SERDIC AEye360, Utilizes AI-powered 360-degree

-

Payment

T/T

-

MOQ

1 ea

-

Supply Ability

9,999,999 ea per One-Time

-

Supply Details

Customization

Negotiable

-

Country of sale

Asia, Middle East, Europe, Americas, World Wide

-

PRICE

-

FOB

USD 30,000.00

(1 ea)

-

ITEM SPECIFICS

-

Brand

Model AEye360SERDIC

-

origin

Republic of Korea

-

Size(Capacity)

23.1 cm (W) × 6.9 cm (D) × 20 cm (H)

-

Material

ABS

-

Color

Black

-

Weight

2kg

PRODUCT DESCRIPTION

AEye360

Service Overview

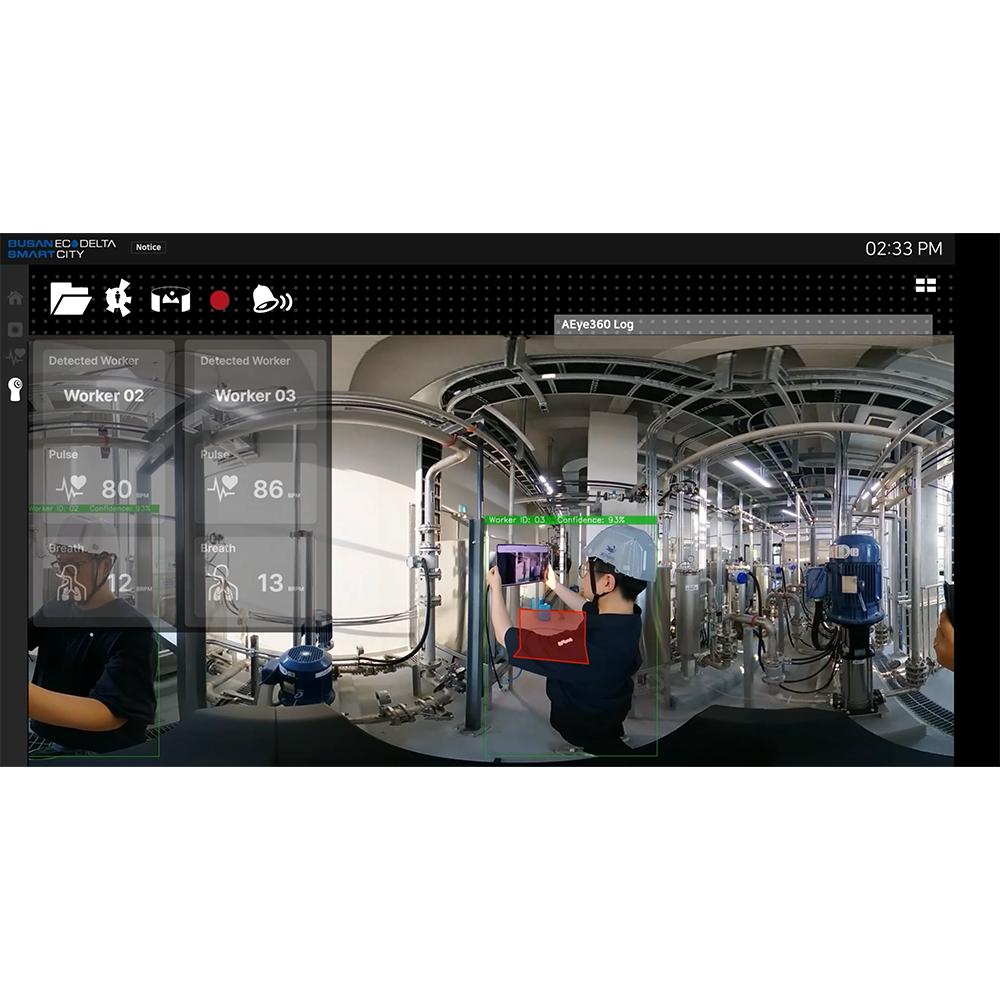

1. Utilizes AI-powered 360-degree cameras to monitor industrial environments in real time and automatically detect potential hazards.

2. Enables bi-directional communication between field workers and the control center through AI-based gesture recognition and real-time inference.

3. Integrates multi-environment sensors to detect harmful substances such as CO₂, fine dust, and specific gases, ensuring comprehensive safety management.

4. Reduces blind spots with a single camera, eliminating the need for multiple CCTV units—offering a low-cost, high-efficiency safety solution.

2. Enables bi-directional communication between field workers and the control center through AI-based gesture recognition and real-time inference.

3. Integrates multi-environment sensors to detect harmful substances such as CO₂, fine dust, and specific gases, ensuring comprehensive safety management.

4. Reduces blind spots with a single camera, eliminating the need for multiple CCTV units—offering a low-cost, high-efficiency safety solution.

Key features

1. Real-time recognition of gestures, falls, and collapses using 3D object detection and pose estimation.

2. 3D reconstruction of accident scenes through 360-degree depth estimation for spatial analysis and root cause identification.

3. Safety zone monitoring with configurable x-alerts when personnel or objects enter restricted areas.

4. Non-contact health monitoring via AI-based facial recognition, respiratory rate, and heart rate estimation.

5. On-device AI inference without the need for external servers, enabling mobile deployment and real-time analysis.

2. 3D reconstruction of accident scenes through 360-degree depth estimation for spatial analysis and root cause identification.

3. Safety zone monitoring with configurable x-alerts when personnel or objects enter restricted areas.

4. Non-contact health monitoring via AI-based facial recognition, respiratory rate, and heart rate estimation.

5. On-device AI inference without the need for external servers, enabling mobile deployment and real-time analysis.

Advantages

1. Covers blind spots with a single 360-degree device, replacing multiple fixed cameras and minimizing setup complexity.

2. Integrates seamlessly with digital twin platforms, enabling intuitive 3D visualization and monitoring.

3. Fully mobile solution without the need for ceiling or wall installation; no external AI server required.

4. Real-time video streaming over both internal and external networks, with minimal latency (~0.5s).

5. Operates on low power using lightweight AI models optimized for embedded systems.

6. Real-time streaming with simultaneous AI processing on the device, supporting multiple client connections.

2. Integrates seamlessly with digital twin platforms, enabling intuitive 3D visualization and monitoring.

3. Fully mobile solution without the need for ceiling or wall installation; no external AI server required.

4. Real-time video streaming over both internal and external networks, with minimal latency (~0.5s).

5. Operates on low power using lightweight AI models optimized for embedded systems.

6. Real-time streaming with simultaneous AI processing on the device, supporting multiple client connections.

How to Use

1. Power on the device and connect to the communication network.

2. Access the dashboard via a browser or monitoring platform.

3. View live video feeds and sensor data, including x-alerts for detected hazards.

4. Submit reports with images or video clips directly from the field.

5. Analyze AI inference results and 3D reconstructions of incidents via the control platform.

6. Monitor worker biometrics and receive automatic x-alerts for abnormal conditions.

2. Access the dashboard via a browser or monitoring platform.

3. View live video feeds and sensor data, including x-alerts for detected hazards.

4. Submit reports with images or video clips directly from the field.

5. Analyze AI inference results and 3D reconstructions of incidents via the control platform.

6. Monitor worker biometrics and receive automatic x-alerts for abnormal conditions.

FAQ

Q1. Is a separate AI server required for analysis?

A1. No, AI inference is performed directly on the device using built-in computing capabilities.

A1. No, AI inference is performed directly on the device using built-in computing capabilities.

Q2. Can the device be used in mobile or battery-powered environments?

A2. Yes, it features a lightweight AI model optimized for low power consumption and mobility.

Q3. Does it support real-time communication with the control center?

A3. Yes, gesture recognition enables communication without physical input, and x-alerts are instantly relayed.

Q4. How is the device installed?

A4. It requires only power and network connection—no complex infrastructure is needed.

Company Overview

SERDIC is an innovative startup developing a web-based Digital Twin platform, AI agents, and simulation technologies to enable efficient digital transformation across industrial sites.

With a focus on simplifying and accelerating industrial digitalization, SERDIC offers a modular suite of transformation solutions tailored for seamless integration. By combining AIoT with data-driven AI technologies, the platform delivers real-time monitoring, anomaly detection, predictive maintenance, and simulation-based visualization — all within a single, web-accessible Digital Twin environment.

With a focus on simplifying and accelerating industrial digitalization, SERDIC offers a modular suite of transformation solutions tailored for seamless integration. By combining AIoT with data-driven AI technologies, the platform delivers real-time monitoring, anomaly detection, predictive maintenance, and simulation-based visualization — all within a single, web-accessible Digital Twin environment.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Jinkyu Kang

SHIPPING

Shipping from :

Republic of Korea

- 23 Seokgye-ro 18-gil, Nowon-gu, Seoul (01886)

SERDIC Inc.

The person in charge

Jinkyu KangAddress

23 Seokgye-ro 18-gil, Nowon-gu, Seoul (01886)

Introduction

SERDIC is an innovative startup developing a web-based Digital Twin platform, AI agents, and simulation technologies to enable efficient digital transformation across industrial sites.

With a focus on simplifying and accelerating industrial digitalization, SERDIC offers a modular suite of transformation solutions tailored for seamless integration. By combining AIoT with data-driven AI technologies, the platform delivers real-time monitoring, anomaly detection, predictive maintenance, and simulation-based visualization — all within a single, web-accessible Digital Twin environment.

-

- Business Type :

- Knowledge Service

-

- Main Product :

- Web-Based Digital Twin Platform and AI Solutions

-

- Established :

- 2021-05-24

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- 5~10 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- SERDIC Inc. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★