Sleeve for Sink Roll, Stabilizer Roll, and Correcting Roll in CGL Lines

-

Payment

L/C(sight) , T/T

-

MOQ

1 ea

-

Supply Ability

9,999,999 ea per One-Time

-

Supply Details

Customization

Negotiable

-

Country of sale

Asia, Middle East, Americas, World Wide, Europe

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model Sleeve for Sink RollBK AMSOL

-

origin

Republic of Korea

-

Size(Capacity)

Custom Design

-

Function

The sleeve serves as a wear-resistant interface between the roll shaft and the outer roll shell, pro

-

Dimensions

Custom made

-

Weight

Custom made

-

Package Includes

Custom made

PRODUCT DESCRIPTION

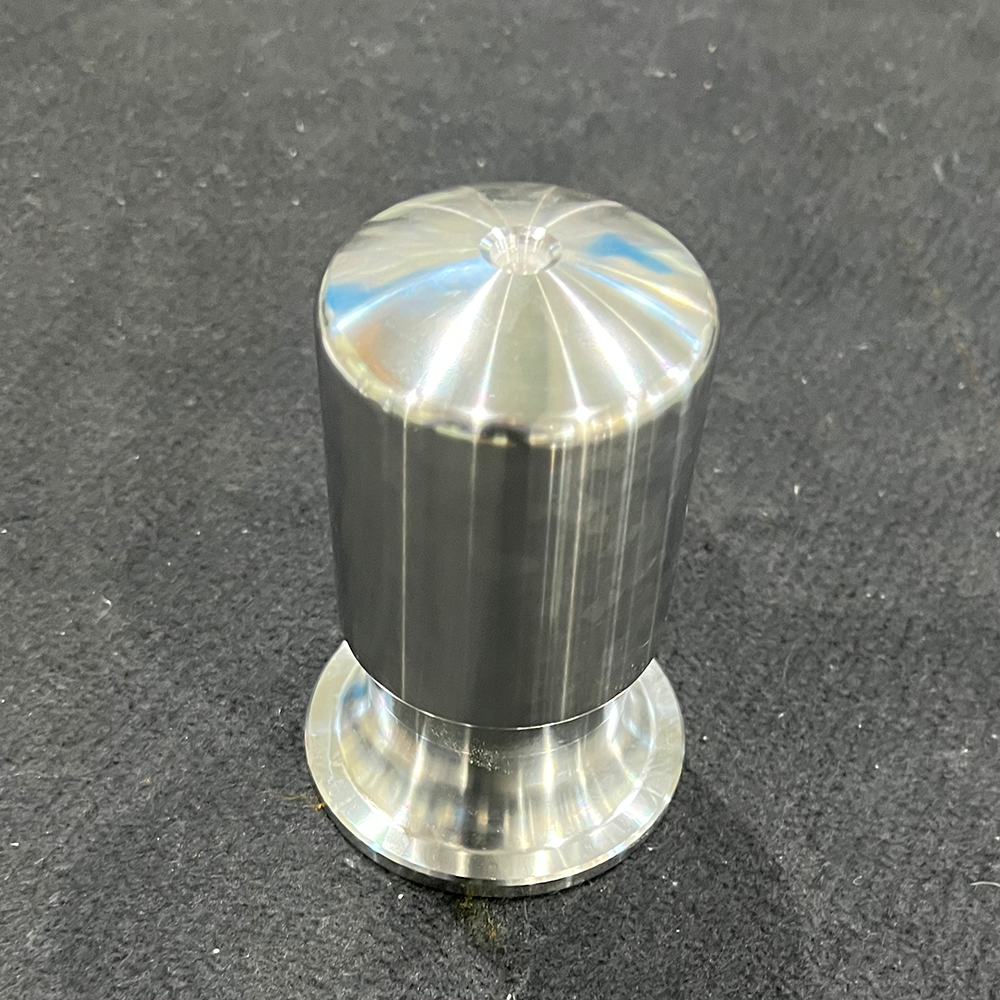

Sleeve for Sink Roll, Stabilizer Roll, and Correcting Roll in CGL Lines

General Description

In Continuous Galvanizing Lines (CGL), rolls such as Sink Rolls, Stabilizer Rolls, and Correcting Rolls operate under extreme heat and corrosion conditions in molten zinc or aluminum baths. The sleeve is a critical component placed between the roll shaft and outer shell to protect against wear, thermal stress, and chemical attack. It ensures stable rotation and extends the lifespan of key roll components in high-temperature galvanizing environments.

Key Features

High-Temperature Alloy Composition:

Manufactured using cobalt- or nickel-based heat-resistant alloys for superior performance above 1000°C.

Precision Casting Process:

Produced using centrifugal or investment casting methods for uniform structure and dimensional stability.

Exceptional Wear Resistance:

Withstands high rotational loads and abrasive environments over long service periods.

Thermal Compatibility:

Engineered to accommodate thermal expansion, minimizing

the risk of slippage or deformation during operation.

the risk of slippage or deformation during operation.

Custom Design:

All aspects including dimensions, key slot geometry,

and material composition are adjustable based on customer requirements.

and material composition are adjustable based on customer requirements.

Benefits & Performance

Significantly reduces wear on roll shafts, increasing equipment life.

Maintains consistent performance under high thermal and mechanical stress.

Excellent resistance to corrosion from molten zinc and aluminum.

Helps reduce maintenance frequency and unexpected downtime.

Contributes to more efficient and reliable continuous galvanizing operations.

Maintains consistent performance under high thermal and mechanical stress.

Excellent resistance to corrosion from molten zinc and aluminum.

Helps reduce maintenance frequency and unexpected downtime.

Contributes to more efficient and reliable continuous galvanizing operations.

Function

The sleeve serves as a wear-resistant interface between the roll shaft and the outer roll shell, providing thermal and mechanical protection in high-temperature galvanizing environments.

Technical Specifications (Example)

| Item | Specification (Typical) |

| Material | Cobalt- or Nickel-based Alloy etc. |

| Outer Diameter (OD) | Ø 40 ~ Ø 220 mm |

| Inner Diameter (ID) | Ø 35 ~ Ø 190 mm |

| Length | 90 ~ 200 mm |

| Casting Method | Sand Casting |

| Origin | Republic of Korea |

About Us

∙ Company Overview

BK AMSOL Co., Ltd. is a specialized manufacturer of high-performance alloy castings, focusing on cobalt- and nickel-based heat-resistant alloys.

With continuous R&D and advanced technical expertise, the company serves a wide range of global industries.

With continuous R&D and advanced technical expertise, the company serves a wide range of global industries.

∙ Factory Information

Established in 1998, BK AMSOL is ISO 9001 certified and supplies major clients such as POSCO and Hyundai Heavy Industries.

The company is equipped with state-of-the-art facilities capable of handling the entire alloy casting process.

In addition to Korea, BKAMSOL works with customers across the globe, including in the United States, Europe, and Asia.

The company is equipped with state-of-the-art facilities capable of handling the entire alloy casting process.

In addition to Korea, BKAMSOL works with customers across the globe, including in the United States, Europe, and Asia.

∙ Our Service

BK AMSOL offers end-to-end alloy casting solutions—from raw material preparation to precision casting and machining.

Its products are widely used in steelmaking, shipbuilding, incineration systems, and the defense industry.

Its products are widely used in steelmaking, shipbuilding, incineration systems, and the defense industry.

∙ Our Policy

BK AMSOL emphasizes a quality-first management philosophy through ISO-based systems and provides customized solutions tailored to the diverse needs of industrial clients.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Telegraphic Transfer : T/T

- Name : WONSOO CHOI

SHIPPING

Shipping from :

Republic of Korea

- 42 Bonchongongdan-gil, Yeongcheon-si, Gyeongsangbuk-do (38899)

BK AMSOL Co., Ltd.

The person in charge

WONSOO CHOIAddress

42 Bonchongongdan-gil, Yeongcheon-si, Gyeongsangbuk-do (38899)

Introduction

Company Introduction

BKAMSOL Co., Ltd. is a specialized manufacturer of high-performance alloy castings, focusing on cobalt- and nickel-based heat-resistant alloys. With continuous R&D and advanced technical expertise, the company serves a wide range of global industries.

Factory Info

Established in 1998, BKAMSOL is ISO 9001 certified and supplies major clients such as POSCO and Hyundai Heavy Industries. The company is equipped with state-of-the-art facilities capable of handling the entire alloy casting process.

In addition to Korea, BKAMSOL works with customers across the globe, including in the United States, Europe, and Asia.

Services

BKAMSOL offers end-to-end alloy casting solutions—from raw material preparation to precision casting and machining. Its products are widely used in steelmaking, shipbuilding, incineration systems, and the defense industry.

Company Policy

BKAMSOL emphasizes a quality-first management philosophy through ISO-based systems and provides customized solutions tailored to the diverse needs of industrial clients.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Special Alloy Casting

-

- Established :

- 1998-11-26

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 3,785

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- BK AMSOL Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

![[BK AMSOL] ROLL](/image/goodsImage.do?goods_no=GS2025082148320&image_se_code=MAIN_THUMB174)