ITEM SPECIFICS

-

Brand

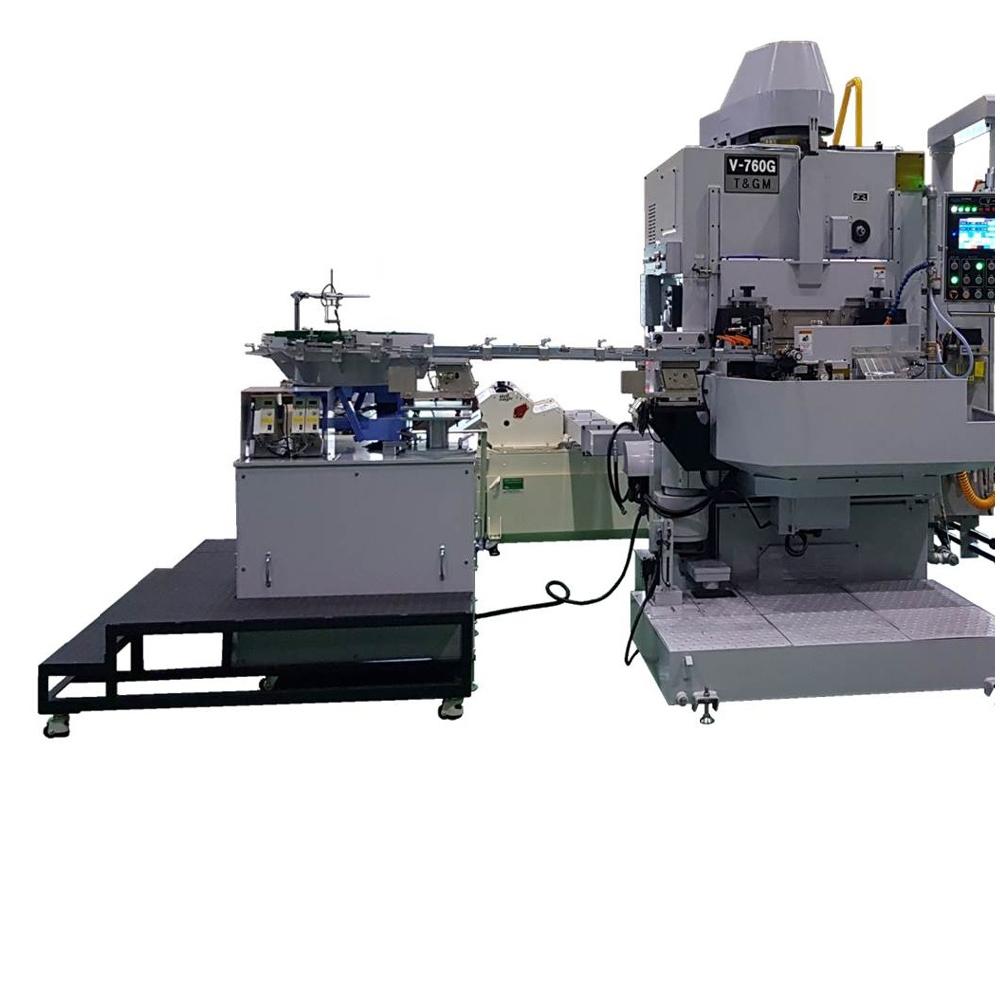

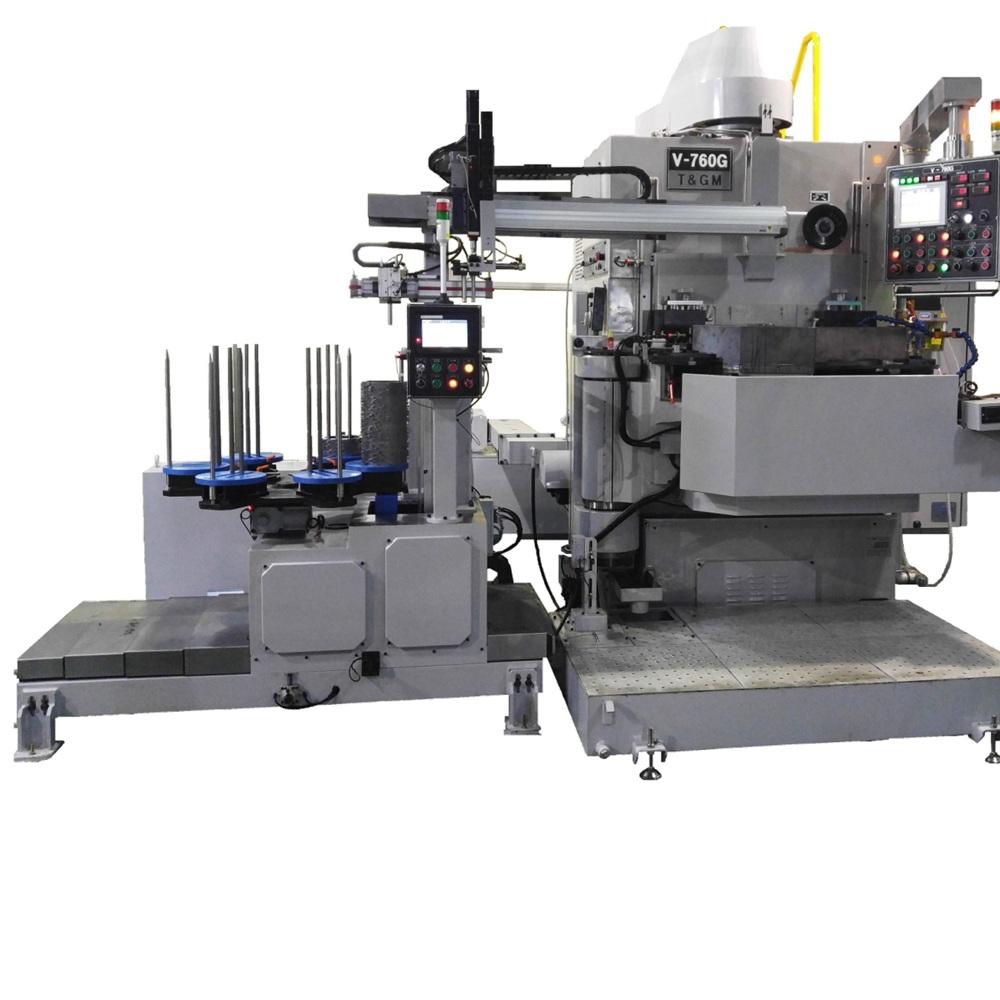

Model V-760GT&GM

-

origin

Republic of Korea

-

Size(Capacity)

4165 x 4900 x 3300 mm

PRODUCT DESCRIPTION

V-760G(Vertical two head planar grinder) containing high technology is a highly reliable machine to face broad grinding as high-performance, high-efficiency and high-accuracy device that can grind a thin plate(minimum 0.8mm) as well as cutting strongly.

This facilitates the exchange of grinding stone and carrier due to the tilting strudture of carrier device x-frame, and realizes strong cutting and smooth grinding through the adoption of large-capacity spindle driven motor(30kw inverter driven)

The grinding stone angle adjuster installed at the top of spindle has an easily controllable structure by worker and is designed of a tilting structure enable fine, precise and accurate control to enable the realization of efficient work through it's convenience and minimized angle control time.

The dressor has a strongly supported precise bearing structure to exert high performance in enhancing the grind ability and accuracy of a work through the exact and prompt simultaneoue dressing of top and bottom grinding stones.

With attached device, automatically work with best convenience

Product name : Vertical Double Disc Grinding Machine

Brand name : T&GM

Type : Vertical

Condition : Brand new

Size/Dimension : 4,165 x 4,900 x 3,300mm

Weight : 11,000kg

Applicable Industries : semiconductor, auto parts grinding, Robot parts grinding, precision grinding work, air conditioner, washing machine, etc.

Warranty : 1 year

Certification : if need, we can proceed /

Frame : Special cast iron x-frame with outstanding rigidity and vibration absorption power.

pindle assembly : Composite spindle assembly suitable for ultra-precise grinding.

Operaton panel : Maximization of convenience through ergonomic arrangement considering worker's action radius.(containing 8 inch touch screen)

Angle adjuster : fine angle adjuster to satisfy parallelism, flatness and dimension tolerance.

Dressing device : Automatic dresser to realize grinding surface roughness and dimension accuracy.

Automatic measurement device : Automatic compensation of the grinding stone wear amount by directly reading the dimension accuracy of product(special option)

Grinding method : Rotary carrier grinding method/Carrier pitching in-feed method(Option)

Grinding stone head device :

Grinding stone size : pie760 x 75 x pie220

RPM : 0 ~ 860 RPM

Revolution method : Regular and reverse switching possible

Maximum distance between top and bottom grinding stone : 90mm

Feeding speed : 0 ~ 150 mm/min - AC Servo motor

Grinding compensation : 0.001 mm ~ 0.099 mm / arbitrary setting

Dress compensation : 0.001 mm ~ 0.099 mm / arbitrary setting

Dresser :

Pitching method : Hydraulic driving method

Arm type : Reciprocation pitching method

Tool : Diamond dresser

Dresser pitching setting : Touch input method / arbitrary setting

Work feeder :

Feeding method : Rotary carrier type

Carrier size - outer diameter : pie900 mm

Carrier RPM : Non-step variable speed change

Feeding speed : 0 ~ 28.3 m/min

Work Supplier : Portable magazine loading inputing method

Work Discharger : Chute automatic discharge

Motor :

Spindle : 22KW4P(30KW4P)

Carrier drive : 1.5KW AC Servo motor

Grinding stone cut : 1.8KW AC Servo motor

Hydraulic unit : 1.5KW 4P

Lubrication pump : 0.02KW 2P

Front coolant pan pump : 0.1KW 2P

Main coolant pump : 1.5KW 2P

Magentic separator : 0.06KW 4P -360L/m

Chiller : 1.5KW 2P

Coolant supplier :

Main tank and pump : 1200L, 260L/min

Thermostat chiller : Cooling capacity 12,000 kcal/h

Thermostat heater : Electric heating type(option)

Auxiliary tank and pump : 180L, 45L/m

Electricity and operation method :

Main controller : Body attached type - mechanically and electrically combined type

Operation method : 8 inch touch panel

Manual cutting method : Use of M.P.G

Installation area(W x D x H) : 4,165 x 4,900 x 3,300

Approximate machine weight : 11,000kg

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : JONG SIK LIM

SHIPPING

Shipping from :

Republic of Korea

- 46 Oksan-ro, Seo-gu, Daegu (41728)

Eurasia International

Eurasia International

https://tradekorea.com/product/detail/P834046/Rotary-grinding-machine.html Seller_MailThe person in charge

Jong Sik LimAddress

46 Oksan-ro, Seo-gu, Daegu (41728)

Introduction

* Small size, Middle size Korean product exporting company

* Main Item

- Textile dying processing machinery(pre process, after process) :

Turbo steam type Continuous Scouring Range.

Turbo type Continuous Washing Range.

Turbo type Continuous Desizing, Scouring and Bleaching Range.

- Sizing machine for textile producing factory

- KF 94 Facial Mask(Health Mask)

-

- Business Type :

- Trading Company

-

- Main Product :

- Continuous Scouring Range

-

- Established :

- 2013-09-23

-

- Total Annual Revenue :

- Less than 100 million (KRW)

-

- Total Employees :

- Less than 5

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- Less than 100 million (KRW)

-

- Total export revenue (previous year in USD)

- 0

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- Eurasia International Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

SUPPLIER BEST

- No Items