ITEM SPECIFICS

-

Brand

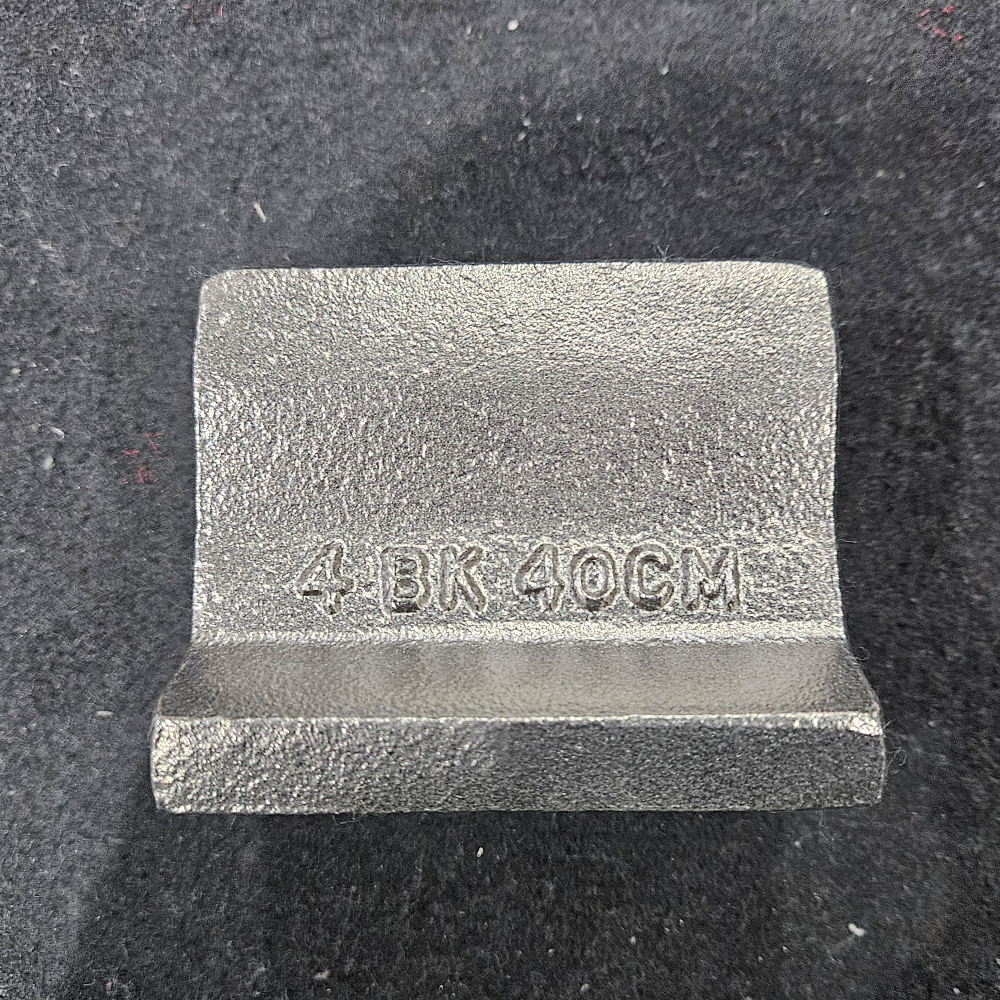

Model SkidBK AMSOL

-

origin

Republic of Korea

-

Size(Capacity)

Custom Design

-

Function

A skid is a structural component used inside reheating furnaces to stably support heavy materials su

-

Dimensions

Custom made

-

Weight

Custom made

-

Package Includes

Custom made

PRODUCT DESCRIPTION

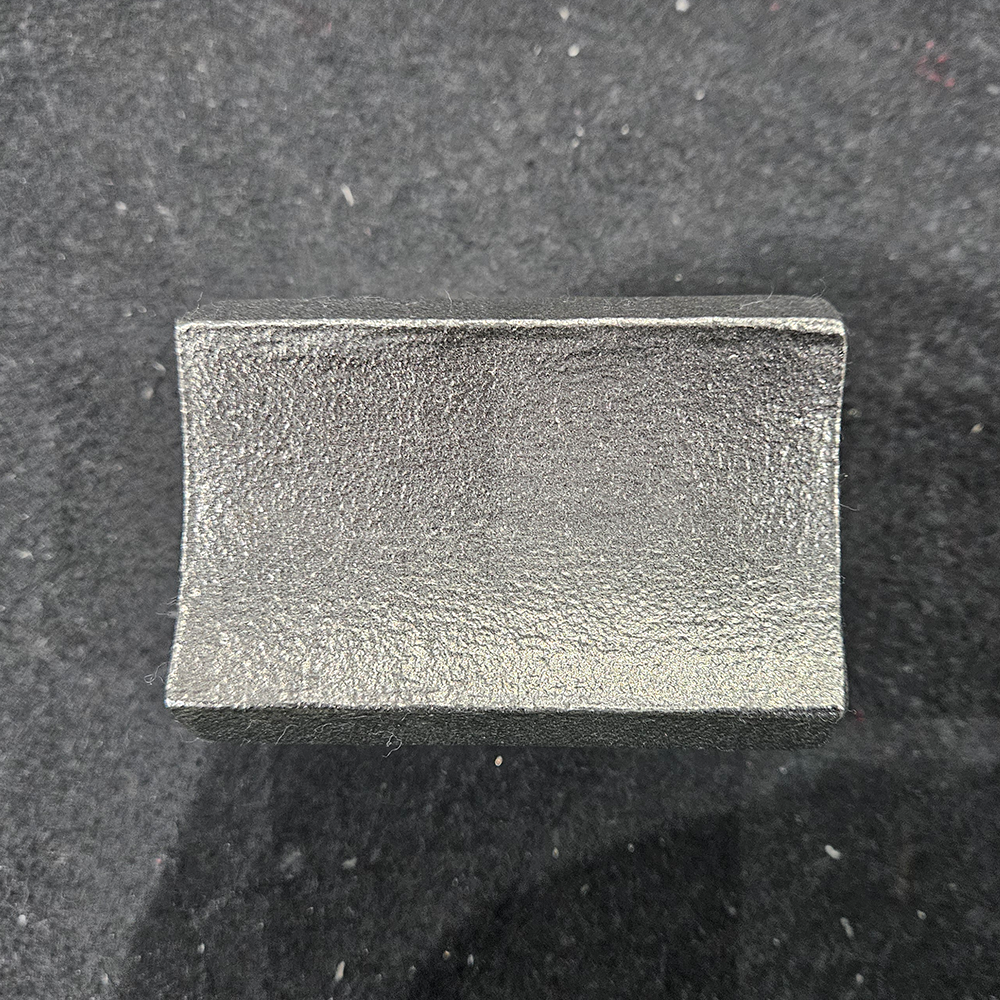

Skid for Walking Beam Reheating Furnaces

General Description

A skid is a heat-resistant structural component used in reheating furnaces to support and elevate heavy steel materials such as slabs and blooms, ensuring even heat distribution, reducing direct contact with the furnace floor, and enhancing both thermal efficiency and equipment durability.

Key Features

Casting Technology:

Manufactured using sand casting processes to ensure high density, uniform microstructure, and precise dimensional accuracy.

High Load Support:

Provides stable support for heavy steel materials, effectively distributing high loads without deformation even under extreme temperatures — designed specifically for such demanding conditions.

Customizable Design:

Shape, wall thickness, and material can be tailored according to customer specifications.

Benefits & Performance

High Load Endurance

Supports and distributes the weight of heavy steel products without deformation, even under extreme temperatures—designed specifically for high-stress environments.

Improved Heat Efficiency

Maintains a gap between steel and furnace floor to enhance airflow and ensure uniform heating, reducing energy consumption.

Extended Service Life

Made from heat- and oxidation-resistant alloys to withstand repeated thermal cycling, minimizing wear and maintenance frequency.

Structural Protection

Acts as a thermal and mechanical buffer, protecting core furnace components from direct stress and damage.

Function

A skid is a structural component used inside reheating furnaces to stably support heavy materials such as slabs or blooms under high-temperature conditions. It plays a critical role by evenly distributing loads and maintaining a slight gap between the steel and the furnace floor, thereby minimizing direct contact and enhancing heating efficiency.

Additionally, skids are made from materials with excellent heat and oxidation resistance to withstand repeated exposure to high temperatures and thermal shocks. This helps protect key components within the furnace and contributes to extending the overall service life of the equipment.

Additionally, skids are made from materials with excellent heat and oxidation resistance to withstand repeated exposure to high temperatures and thermal shocks. This helps protect key components within the furnace and contributes to extending the overall service life of the equipment.

Technical Specifications (Example)

| Item | Specification (Typical) |

| Material | Cobalt-based, Chromium-based, Nickel-based alloy, or others |

| Casting | Sand Casting |

| Origin | Republic of Korea |

Note:

All skids can be fully customized in material, shape, and dimensions to meet the specific operational conditions and customer requirements.

About Us

∙ Company Overview

BK AMSOL Co., Ltd. is a specialized manufacturer of high-performance alloy castings, focusing on cobalt- and nickel-based heat-resistant alloys.

With continuous R&D and advanced technical expertise, the company serves a wide range of global industries.

With continuous R&D and advanced technical expertise, the company serves a wide range of global industries.

∙ Factory Information

Established in 1998, BK AMSOL is ISO 9001 certified and supplies major clients such as POSCO and Hyundai Heavy Industries.

The company is equipped with state-of-the-art facilities capable of handling the entire alloy casting process.

In addition to Korea, BKAMSOL works with customers across the globe, including in the United States, Europe, and Asia.

The company is equipped with state-of-the-art facilities capable of handling the entire alloy casting process.

In addition to Korea, BKAMSOL works with customers across the globe, including in the United States, Europe, and Asia.

∙ Our Service

BK AMSOL offers end-to-end alloy casting solutions—from raw material preparation to precision casting and machining.

Its products are widely used in steelmaking, shipbuilding, incineration systems, and the defense industry.

Its products are widely used in steelmaking, shipbuilding, incineration systems, and the defense industry.

∙ Our Policy

BK AMSOL emphasizes a quality-first management philosophy through ISO-based systems and provides customized solutions tailored to the diverse needs of industrial clients.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Telegraphic Transfer : T/T

- Name : WONSOO CHOI

SHIPPING

Shipping from :

Republic of Korea

- 42 Bonchongongdan-gil, Yeongcheon-si, Gyeongsangbuk-do (38899)

BK AMSOL Co., Ltd.

The person in charge

WONSOO CHOIAddress

42 Bonchongongdan-gil, Yeongcheon-si, Gyeongsangbuk-do (38899)

Introduction

Company Introduction

BKAMSOL Co., Ltd. is a specialized manufacturer of high-performance alloy castings, focusing on cobalt- and nickel-based heat-resistant alloys. With continuous R&D and advanced technical expertise, the company serves a wide range of global industries.

Factory Info

Established in 1998, BKAMSOL is ISO 9001 certified and supplies major clients such as POSCO and Hyundai Heavy Industries. The company is equipped with state-of-the-art facilities capable of handling the entire alloy casting process.

In addition to Korea, BKAMSOL works with customers across the globe, including in the United States, Europe, and Asia.

Services

BKAMSOL offers end-to-end alloy casting solutions—from raw material preparation to precision casting and machining. Its products are widely used in steelmaking, shipbuilding, incineration systems, and the defense industry.

Company Policy

BKAMSOL emphasizes a quality-first management philosophy through ISO-based systems and provides customized solutions tailored to the diverse needs of industrial clients.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Special Alloy Casting

-

- Established :

- 1998-11-26

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 3,785

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- BK AMSOL Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

![[BK AMSOL] ROLL](/image/goodsImage.do?goods_no=GS2025082148320&image_se_code=MAIN_THUMB174)